Wire and Arc Additive Manufacturing (WAAM) is an additive manufacturing technology that uses a welding arc as a source of energy and welding wire as an adding material. Recently it grew in research popularity and is slowly integrating into the industry. The biggest advantage of this technology is the ability to build products with great volume. It allows lower manufacturing costs by reducing the amount of waste material and shorter time from a concept to a product. It also allows a higher degree of design and construction flexibility and geometries that are too complex for conventional technologies.

The basis of additive technologies is the motion control system, the heat source, and the additive material. In the WAAM process, the energy source is an electric arc, and the adding material is added in the form of a welding wire while the movement is performed with a robotic manipulator or other CNC machines.

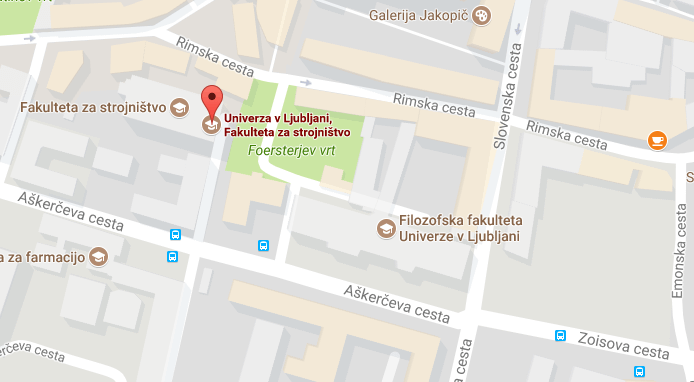

Tests are carried out in the laboratory using the ABB IRB140 robot manipulator and the Fronius CMT current source, as well as a CNC machine manufactured in the LAKOS laboratory using the Daichen-Varstroj Welbee 500L current source. We deal with the design of process windows for individual materials. We perform tests on aluminum (4000, 5000 series), stainless, structural and special steels (maraging). We test different construction strategies according to the desired parameters.

We participate in projects both at the national and European levels (MARTINA, PKP), and we also carry out research and development through doctoral and master’s theses.

Simulation of robotic additive manufacturing with Delfoi Robotics: