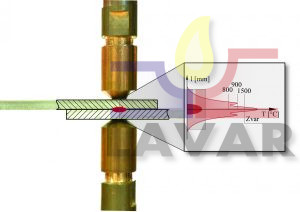

In electric resistance welding, we utilize the thermal energy that generates when an electrical current is passed through two or more welding pieces and a mechanical force that compresses the welders during welding. The process is divided into resistance spot welding, resistance wheel welding, resistance butt welding with pressure, incendiary resistance welding, resistance soldering, and high-frequency resistance welding.

Resistance spot welding (RSW) is one of the most common methods of resistance welding. It is mostly used in the automotive and electrical industries, and in the production of household appliances. It is currently the most robotic welding process.

Our laboratory has three machines for resistance spot welding, namely:

– Kočevar and the Sons (a modern computer-assisted machine with an inverter source)

– Zagreb Electrode TA-60S (classic machine with transformer source)

– Iskra NVK 3104 (2.5 kW low power welding machine)

Useful:

-An online application for determining the weldability of material pairs

–Online welding troubleshooting application

–Basics of resistive spot welding

–Resistance spot welding application

Links:

–Kočevar and the Sons d.o.o.

Interesting clips:

Some photos from the lab: